Why You Need a Circle Burner for A Precise and Accurate Circular Cut

Steel and metal components are an integral part of many industries. They provide immense stability and strength. One of the two most crucial processes in various sectors is cutting and welding. The process of cutting involves cutting out or separating a segment of metal or steel from the source. On the contrary, welding is all about joining together steel or metal components.

Both of the techniques, cutting, and welding, are not simple and need careful technique and appropriate equipment. Welding involves the use of high temperatures to form a weld or a joint between two pieces of metal. The heat comes from oxygen as well as oxy fuels like natural gas, propane, and acetylene.

The surfaces of metal and steel components are pretty sturdy. Thus, it is not easy to cut through them. You can find some heavy-duty metal cutters, but it takes a great deal of strength and effort. Also, these cutters can only be cut in a straight line. Therefore, it can be challenging when you want to cut a spherical shape out of a steel pipe or a metal surface. That is when a circle burner comes in handy.

You can use a single-point tool. It has a single edge and is appropriate for cutting and shape. Multi-point tool, on the other hand, is suitable for drilling and grinding purposes. The important things to take into account before selecting a metal tool include:

- The resistance to usual wear and tear throughout the cutting process

- The toughness and hardness of intensive heat shouldn’t deform the cutter’s material

- The strength of the cutter

- 6 Advantages of Using Custom Saws

There are many different techniques for cutting steel or metal plates. The method you choose depends on the thickness and type. Some techniques are more expensive than others.

The Important Use of Circle Shape Cutter

According to experts, the cutter’s material should be sturdier than the material you are trying to cut with it. Your cutting tool should be able to resist the intense heat generated by the oxy-acetylene flame. Cutting a circular shape out of a metal or steel plate can be considerably challenging and complex.

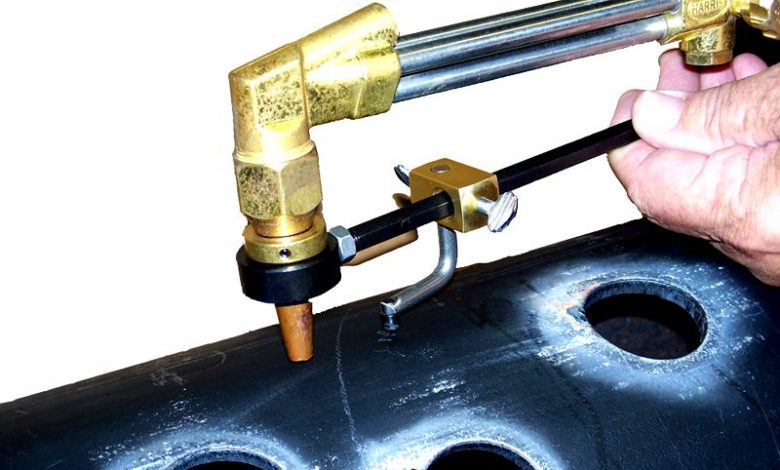

The first thing a worker needs to do is find the proper equipment that can cut through a metal part in a spherical shape. It is unfortunate that we don’t have a lot of tools that can cut in a spherical shape. That being said, the development in technology offers a way through the use of a circle shape cutter. The circular cutter operates along with a torch attachment that supplies the flame.

A circle metal cutter is an ideal tool for making a precise spherical cut at every angle. Furthermore, using this tool saves both effort and time. Also, the circle cutter is an important tool in industrial construction, auto repair shops, fabrication stores, and metal scraping. The tool is important for achieving accuracy and precision, which is difficult when you are trying to get a spherical cut. You can get cuts between 1-12 inches with 24 inches in diameter.

The Common Method of Cutting Metal Parts

For the longest time, oxy-acetylene cutting and welding were some of the most common methods because of their efficiency and affordability. However, with the recent advancements, arc welders are ideal for cutting different metal shapes. They not only provide consistent cuts but are also super-fast.

The oxy-acetylene process came into existence in 1903. When you pair fuel such as acetylene with oxygen, it generates a flame that burns at 6,332 ºF. During the melting process, a torch is used to make welds or cuts in the material. Acetylene is a common choice because it can generate intense temperature levels. Some other oxyfuel options are natural gas, hydrogen, propane, and propylene. Oxidation is when the oxyfuel combines with oxygen to create heat and melt the metal piece.

The plasma torch has the ability to cut through a wall that has a thickness of 3cm. You can easily attach the circle cutter with the plasma or oxy-acetylene torch. In addition, you can cut holes of any size radius without any issue. Furthermore, you have to place the sharp point on the central park when cutting the metal segment.

The Importance of Ensuring Safety Rules

The processes of cutting and welding use high temperatures. Thus, it is incredibly important to have proper safety guidelines in place. A worker who participates in metal cutting has to wear goggles, a helmet, and some protective gloves for protection against sparks and heat. 6 Advantages of Using Custom Saws

Following are the steps to achieve a circular metal cut:

- Place a two-by-two wooden piece parallel on the work table. Now place the material you are trying to cut across the two wooden pieces. Then use a clamp-on both sides for holding the material and wooden pieces onto the surface of your work table.

- Then mark the center of the spherical hole present on the material. Use a drill to drill a hole into the material at the marked point. Use the drill bit as your guide for this process.

- Install the circle cutting attachment and the cutting bit to the rotary Now you need to adjust the circle cutting attachment to the size you are trying to cut. Also, the worker has to consider the material’s thickness too.

- Hold the circle cutting attachment in the knob in one hand and the rotatory tool in the other. Then you turn on the tool. Using a single smooth motion, place the guide pin inside the guide hole and simultaneously enable the cutting bit to cut and plunge through the material.

- Next, you make the rotary tool move in a circle. Complete the rotation of the cutting tool to make sure that the arc that is cut is spherical. Now turn off the flame.

- It will take around 1-2 minutes for the metal piece to cool down. Then use a hammer to force the metal piece out of the metal surface.

A circle cutter is a useful tool that can conveniently cut through stainless steel and steel alloys. Also, you can carry out even challenging metal cutting tasks. The worker performing the cutting task has to go through the instruction manual and follow all the safety guidelines.

Final Words

The top-quality circular-cut demands a premium quality tool. A circle burner does an effective job at fulfilling this purpose. It is durable, easy to use, and incredibly efficient. The tool is ideal to get a precise and clean cut in any situation anytime.